Industrial Water Chiller: A Complete Guide with Facts and Insights

Industrial water chillers are specialized cooling systems designed to remove heat from processes, equipment, or environments in industrial settings. They work by circulating chilled water or a coolant through machinery, production lines, or facilities to maintain optimal temperatures.

Industries such as plastics, food processing, pharmaceuticals, manufacturing, data centers, and HVAC systems rely heavily on water chillers to ensure consistent performance and avoid overheating. Without them, sensitive machinery could fail, production quality could decline, and operational costs could rise due to inefficiencies.

These systems exist because industrial processes often generate large amounts of heat, which must be managed effectively to maintain safety, efficiency, and product quality.

Importance – Why industrial water chillers matter today

Industrial water chillers are essential for modern operations across many sectors:

-

Manufacturing: Machines like injection molding and CNC equipment produce heat that must be controlled.

-

Pharmaceuticals: Medicines and vaccines require strict temperature control during production and storage.

-

Food and beverage: Chillers help preserve quality, extend shelf life, and maintain hygiene standards.

-

Data centers: Cooling is critical to prevent server overheating and maintain uptime.

-

Energy efficiency: By recycling water and optimizing cooling, modern chillers reduce energy use and operating costs.

The importance also extends to sustainability. Newer chillers are designed to consume less power, use eco-friendly refrigerants, and minimize water waste—helping companies meet global climate goals.

Recent Updates – Key trends and developments

Over the past year, industrial water chillers have seen several advancements:

-

Energy -competent design (2024–2025): Manufacturers focus on variable speed compressors, advanced heat exchange and smart control systems to reduce energy consumption.

- ECO -friendly refrigeration medium: In 2024, the rules inspired industries to use low -GWP (global warming potential) refrigeration media such as R -32 and R -1234Yf.

- Integration with IoT: Smart chills now contain sensors and future maintenance equipment, distance monitoring and reduction of closures.

- Hybrid systems: Some companies combine air colleagues and water -cooled techniques to improve flexibility and adapt to different climat

Laws or Policies – Regulations affecting industrial water chillers

Industrial water chillers are affected by several laws and policies depending on the region:

-

Environmental regulations: Many governments regulate the type of refrigerant used because of their environmental impact. The Kigali change for the Montreal Protocol (adopted globally) takes down Hydrophlorocarbon (HFC).

- Energy efficiency standards: In the United States, Energy Department (DOE) determines the minimum energy efficiency level for chillars. Europe implements similar standards under Ecodesign Instructions.

- Politics for water use: In areas facing water shortages, the guidelines for the use of closed loops or hybrid systems encourage to reduce water waste.

- Safety compliance: Chillarer should complete the local safety code on pressure vessels, electrical systems and cold handlin

These policies ensure that chillers not only function efficiently but also minimize harm to the environment and reduce operating risks.

Tools and Resources – Helpful aids for businesses and engineers

For businesses and facility managers looking to choose or manage industrial water chillers, several tools and resources are available:

-

Load calculator: Online tool processes help determine the requirements for cool capacity depending on the type and heat load.

- Energy efficiency calculator: Available from public websites and industry associations, this equipment estimates potential cost savings.

- IoT-based monitoring system: Platforms such as Johnson control metases and Siemens Designo CC, allowing future maintenance and monitoring in real time.

- Industry database: Ahri (air conditioning, heating and cooling institutes) offers certified performance assessments for chillars.

- Training program: Organizations such as Ashrae (American Society of Heating, Refrigerating and Air-Conditioning Engineers) offer courses on chiller operations, safety and stability

A simple comparison table illustrates chiller types:

| Type | Cooling Method | Best Use Cases |

|---|---|---|

| Air-cooled | Uses ambient air | Smaller facilities, data centers, regions with limited water supply |

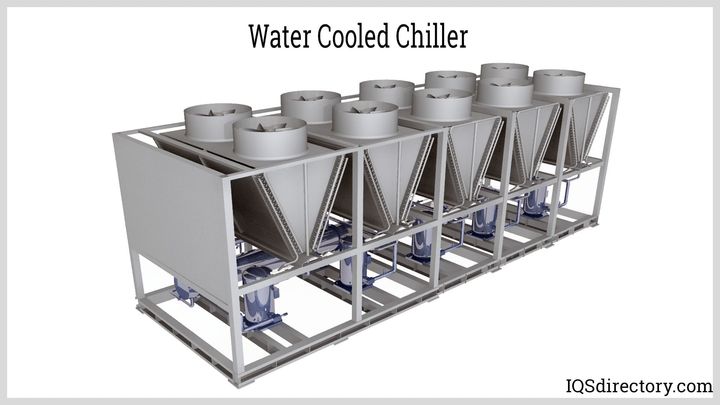

| Water-cooled | Uses cooling towers | Large-scale manufacturing, high heat-load industries |

| Hybrid systems | Combination of both | Flexible operations in changing climates |

FAQs – Common questions about industrial water chillers

Q1. What is the difference between air -cooled and water -cooled cooler?

Air -cooled cooler uses ambient air to spread heat, while water -cooled cooler uses water and cooler. It is easy to install and maintain air -cooled systems, while water -cooled systems are more effective for mass operations.

Q2. How long does an industrial water chiller last?

With proper maintenance, an industrial chiller can last between 15 and 25 years. Factors like operating conditions, water quality, and regular servicing influence lifespan.

Q3. Is industrial chiller environmentally friendly?

Modern Chiller is quickly designed to be environmentally friendly, using low-GWP refrigerant, energy-capable design and water saving systems. Compliance with environmental rules reduces carbon footprint.

Q4. How do I determine the right chiller size for my facility?

The correct size depends on your heat load, process requirements, and operating conditions. Using a load calculator or consulting with a certified engineer is recommended.

Q5. What maintenance is required for industrial water coolers?

Routine functions include checking cold levels, inspecting compressors and pumps, cleaning capacitor pipes and monitoring the system and temperature of the system. Preventive maintenance equipment helps to increase life and reduce shutdown.

Conclusion – The future of industrial water chillers

Industrial water cooler is important for industries that depend on accurate temperature control and energy efficiency. Chillar's role is expanded to areas, with increasing global demand, strict rules and stabilization for stability.

Furthermore, the integration of smart technologies, environmentally friendly refrigerators and hybrid cooling solutions will make the chillars more durable and costs. Companies that invest in advanced cooling systems today not only improve efficiency, but also match future environmental and government requirements.